打开微信扫一扫

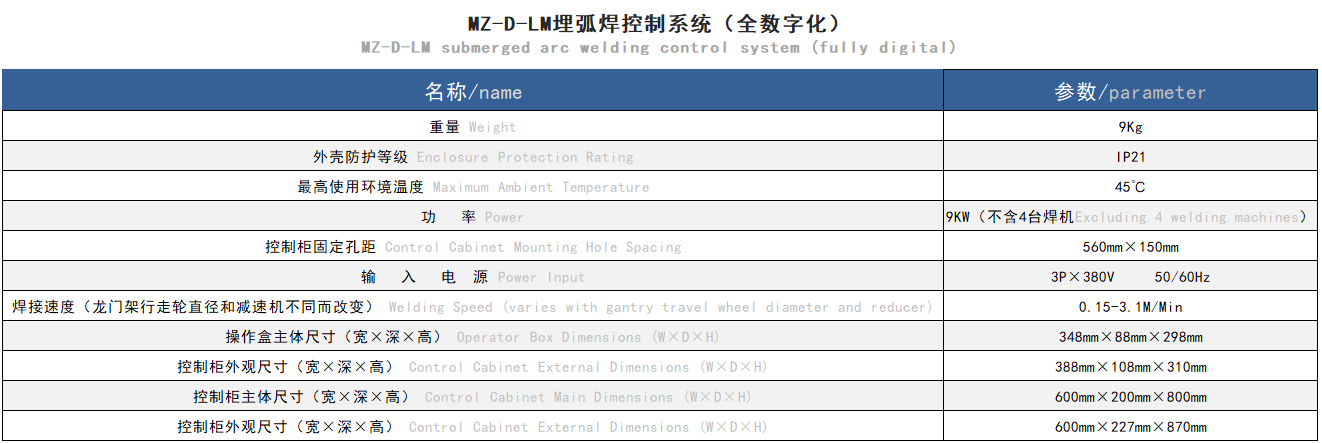

打开微信扫一扫MZ-D-LM埋弧焊控制系统(全数字化)

MZ-D-LM submerged arc welding control system (fully digital)

1、点动送丝时,焊丝接触工件自动停止下送,防止顶弯焊丝和影响引弧。焊丝粘接工件时可强迫送丝。

2、同一机头的直流焊机和交流焊机可同时启停、交流延时启停也可分别启停。

3、在触摸屏上显示参数数据及触控操作,更方便,更直观。

4、参数可断电保存。

5、参数可通过 USB 导出或导入,多焊机可实现参数共享。

6、完善的权限管理,可设置不同级别、不同操作员的权限。

7、报表数据在焊接完成后保存,并可通过 USB 导出。

8、可扩展有线和无线网络控制,并可扩展集控系统进行集中管理。

9、对输出电流进行实时追踪,确保电流输出误差在2%以内。

Product Features

1. When tapping the wire feed, the wire will automatically stop feeding when it contacts the workpiece, preventing the wire from bending and affecting arc initiation. Wire feeding can be forced when bonding workpieces with welding wire.

2. The DC welding machine and AC welding machine with the same head can be started and stopped simultaneously, and the AC delayed start and stop can also be started and stopped separately.

3. Displaying parameter data and touch operations on the touch screen is more convenient and intuitive.

4. The parameters can be saved with power off.

5. Parameters can be exported or imported through USB, and multiple welding machines can achieve parameter sharing.

6. Complete permission management, allowing for the setting of permissions for different levels and operators.

7. The report data is saved after welding is completed and can be exported via USB.

8. Scalable wired and wireless network control, and expandable centralized control system for centralized management.

9. Real time tracking of output current to ensure that the current output error is within 2%.